Categories

The latest content

-

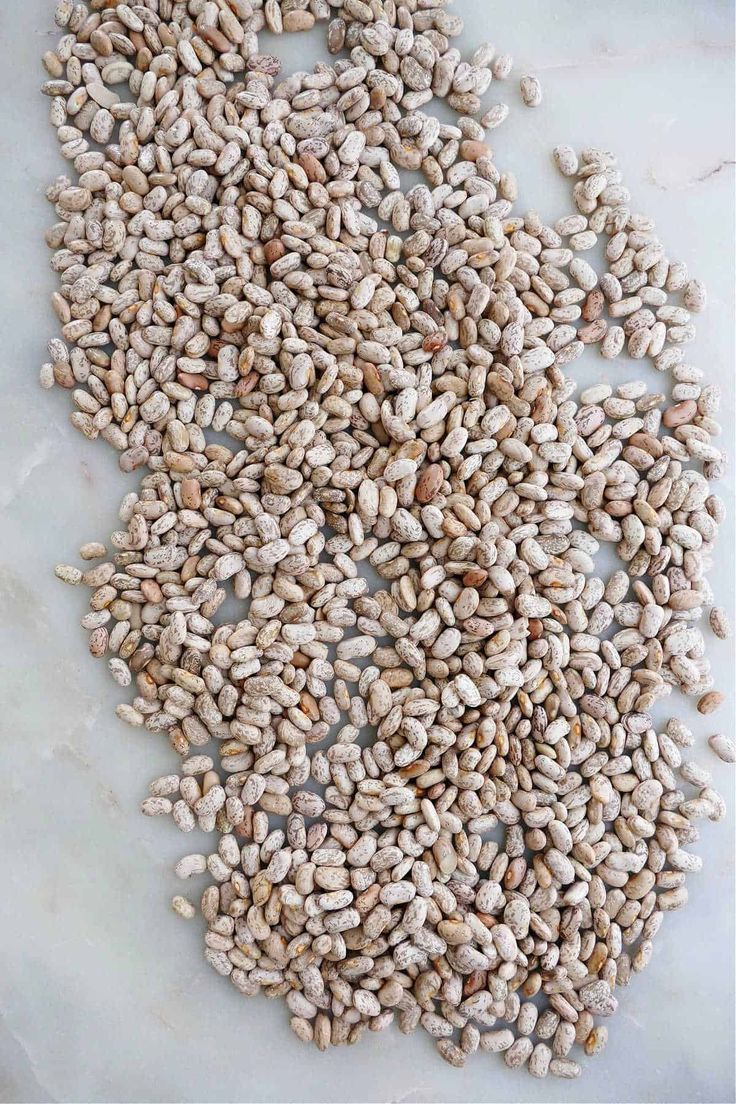

Customs Clearance & Import Regulations for Bulk Iranian Pinto Beans in EU, Middle East & Africa

..

-

Quality Control & Laboratory Testing Standards for Iranian Pinto Beans

..

-

Logistics & Shipping Solutions for Bulk Iranian Pinto Bean Exports

..

-

Minimum Order Quantity (MOQ) & Bulk Pricing for Iranian Pinto Bean Buyers

..

Tags

Quality Control & Laboratory Testing Standards in Cashew Kernel Export

Exporting cashew kernels is far more than packaging and shipping — it’s a meticulous process of quality assurance, laboratory testing, and compliance with international food safety standards. As global buyers demand consistency, purity, and safety, exporters must invest in strict quality control (QC) systems and scientific testing protocols to meet market expectations.

At Tamila Agrifood, we follow a comprehensive quality framework designed to ensure that every cashew kernel batch — whether W180 or broken grade — meets the highest global benchmarks for taste, appearance, and food safety.

1. Why Quality Control Matters in Cashew Exports?

Cashew kernels are one of the most value-sensitive nuts in the global trade. A small variation in moisture, color, or contamination can cause large financial losses or even rejection at customs. For international importers, consistent quality means:

• Extended shelf life and freshness

• Reduced risk of recalls or rejections

• Higher market reputation and customer trust

• Compliance with import regulations (EU, FDA, ISO)

In short, quality control = market credibility.

2. The Multi-Stage Quality Control Process

At Tamila Agrifood, quality inspection begins before harvesting and continues until final container loading. Each stage has a specific protocol designed to detect and eliminate potential defects early.

a. Raw Nut Inspection

Before shelling, raw cashew nuts are tested for:

• Moisture content (should not exceed 10%)

• Size uniformity

• Mold or infestation

• Kernel yield percentage

Only raw materials meeting export-grade standards proceed to processing.

b. Shelling & Peeling Quality Checks

The nuts are steam-treated and hand-shelled with precision.

Quality teams monitor:

• Shell breakage rates

• Kernel damage percentage

• Residual testa (brown skin) levels

• Hygiene compliance of processing lines

c. Grading & Sorting

Cashews are sorted into grades like W180, W210, W240, W320, and Broken using optical sorters and manual inspection under bright light.

Defective or discolored nuts are removed to ensure uniform color and size.

d. Roasting & Drying Control

Temperature and time are calibrated for each grade to prevent over-browning.

• Target Moisture: 3–5%

• Test Equipment: Moisture analyzer or infrared dryer

• Objective: Ensure crisp texture without oil degradation

e. Packaging & Pre-Export Testing

Before shipment, every batch undergoes final lab verification for moisture, aflatoxin, pesticide residue, and microbial safety.

3. Key Laboratory Tests for Cashew Kernel Export

a. Moisture Content Analysis

Excess moisture causes fungal growth and rancidity.

• Standard: ≤ 5%

• Method: Oven-drying or Karl Fischer titration

b. Aflatoxin Detection

Aflatoxins are toxic compounds produced by Aspergillus fungi.

• Accepted Limit (EU): ≤ 4 ppb total aflatoxin

• Test Method: HPLC (High-Performance Liquid Chromatography) or ELISA

c. Microbiological Testing

Ensures product safety and hygiene.

• Tests Include:

o Total plate count

o Yeast and mold count

o E. coli and Salmonella screening

d. Pesticide Residue Testing

Verifies compliance with Maximum Residue Limits (MRLs) set by importing countries.

• Standard: < 0.01 mg/kg (varies by compound)

e. Physical & Organoleptic Evaluation

Experts evaluate kernel color, shape, aroma, and flavor to confirm grade identity and freshness.

4. International Standards & Certifications

To build trust in global markets, exporters must demonstrate compliance with internationally recognized certifications.

Certification / Purpose / Benefit

ISO 22000 / Food safety management / Ensures consistent QC practices

HACCP / Hazard control system / Prevents contamination risks

Halal & Kosher / Religious standards / Expands market reach

BRC / FSSC 22000 / European compliance / Required for retail chain supply

Organic Certification / No chemical or synthetic input / For premium buyers & EU markets

Tamila Agrifood’s partner processing facilities are audited regularly to maintain these standards and assure clients of full traceability and compliance.

5. Advanced Equipment Used in Cashew Testing Labs

Modern cashew processing plants use automated and calibrated instruments for precision analysis, including:

• HPLC Systems for toxin and pesticide analysis

• Spectrophotometers for color consistency

• Moisture Balances for rapid humidity testing

• Metal Detectors & X-ray Scanners for foreign object detection

• Microbiological Incubators for pathogen screening

These technologies not only guarantee quality but also speed up certification processes before export.

6. Common Defects Detected During Quality Checks

Defect / Cause / Prevention Method

Discoloration / Over-roasting or old stock / Controlled roasting & rotation

Rancidity / High moisture or poor storage / Proper drying & nitrogen sealing

Broken Kernels / Mechanical handling / Use gentle conveyance systems

Insect Damage / Poor raw nut selection / Fumigation & sealed storage

Aflatoxin Contamination / Humidity & mold / Sun-drying & regular lab tests

By proactively addressing these issues, exporters can reduce rejection rates and improve buyer satisfaction.

7. Tamila Agrifood’s Commitment to Excellence

At Tamila Agrifood, quality assurance is more than a checklist — it’s a philosophy.

Our QC experts work alongside processing units to ensure every batch of cashew kernels meets:

• International laboratory standards

• Buyer-specific technical specifications

• Consistent color, taste, and shelf stability

Each shipment is accompanied by third-party lab reports, certificate of analysis (COA), and inspection documents for transparency and trust.

8. Final Inspection Before Export

Before loading containers, an independent inspection agency (such as SGS, Intertek, or Bureau Veritas) verifies:

• Weight and packaging integrity

• Container cleanliness and fumigation

• Sampling for moisture and aflatoxin re-testing

Only after passing all quality and compliance checks are cashews cleared for international shipment.

Conclusion

In the competitive world of cashew kernel exports, quality is not negotiable — it’s the key to global success.

From aflatoxin testing and HACCP compliance to real-time laboratory validation, the future belongs to suppliers who invest in scientific quality systems.

At Tamila Agrifood, our unwavering commitment to laboratory excellence and transparent certification ensures that every buyer receives safe, premium-grade cashews that meet and exceed international expectations.

Email: tamilaagrifood@gmail.com

Call / WhatsApp: +989141858935